Practice both domestically and internationally has demonstrated that scientific and meticulous rail maintenance not only eliminates surface defects on rails, ensuring railway operational safety and comfort while preventing premature failure of rolling stock and infrastructure due to vibration, but also extends rail lifespan by 4 to 6 times. This approach reduces traction energy consumption and significantly lowers operational costs. Therefore, rail maintenance is an essential measure for the safe operation of rail transit systems, and rail maintenance equipment is indispensable for rail transit operators and rail maintenance service providers.

Picture1 FGM500A Rail Milling Train Delivered to MTR

Picture1 FGM500A Rail Milling Train Delivered to MTR

Picture 2 FGM Rail Milling Train Operational Rendering

Precision-Driven Silhouette Management

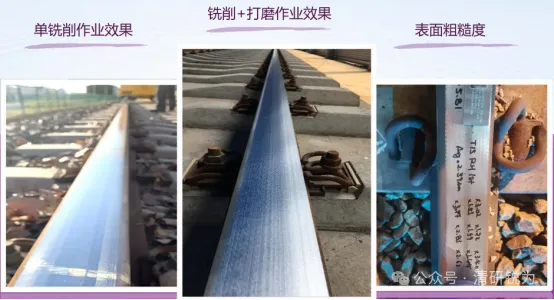

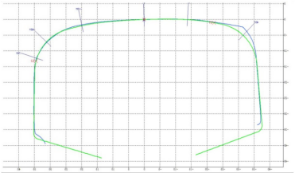

The FGM series Rail Milling Trains employ high-precision forming milling cutters and super-hard grinding tools for efficient rail processing, enabling precise profile management. Eliminating the manual angle control required in traditional methods and eliminating the need to switch grinding modes, rail profile accuracy reaches ±0.1mm, exceeding standard requirements. The control system features gauge correction, high-precision lateral profiling, and predictive detection capabilities, ensuring optimal rail light bands and wheel-rail matching. It enables scientific profile design and supports multiple profile tool configurations. Utilizing unique tool design and optimized blade arrangement, it achieves profile accuracy of ±0.1mm with residual waviness below 0.01mm, meeting requirements without additional grinding. A specialized tool change system enables tool replacement within 10 minutes.

|  |

Picture 3 Profile Accuracy After Operation of FGM Rail Milling Train

Peak-Shaving and Valley-Filling Management for Longitudinal Smoothness

Wave wear is the most common rail defect, posing significant hazards in terms of vibration and noise. It is hereditary and, if not thoroughly eliminated, will recur frequently. Unlike traditional floating grinding methods, the FGM series rail milling trains offer high-precision wave wear treatment. With a vertical profiling length of 900mm, vertical detection accuracy of 0.01mm, and a minimum milling depth of 0.15mm, they are suitable for preventive maintenance. with a maximum depth of 1.5mm to fundamentally eliminate wave wear and other defects. For severely worn sections and welded joints, a single pass achieves smoothness. The FGM series is equipped with a high-precision flexible grinding device for rail polishing, enabling “silent” maintenance.

|  |

Picture 4 Comparison of Rail Corrugation After FGM Rail Milling Train Operation

Disease Management for Wind-Swept Clouds

Scaling and fish-scale pattern must be completely removed to prevent crack propagation leading to rail breakage. Typically, fish-scale pattern exceeds 0.8mm in depth, while scaling exceeds 1mm. Conventional rail grinding requires 8-10 passes to fully envelop the rail, achieving only 0.2mm of removal depth. This necessitates multiple grinding cycles, rendering severe defects nearly impossible to address. The FGM series rail milling trains employ high-efficiency milling technology, achieving a milling depth of 1.5mm on the top surface and 3-5mm on the sides. This enables defect elimination in a single pass.

|  |

Picture 5 Effect of FGM Rail Milling Train on Removing Spalling and Fish-scale Pattern

|  |

Picture 6 Effect of FGM Rail Milling Train Edge Removal

A Pristine and Immaculate Work Environment

Traditional rail maintenance operations have long been criticized for dust pollution and fire hazards. The FGM rail milling trainsoperation produces C-shaped iron chips without sparks, eliminating fire risks and generating no fine particulate dust for a clean working environment. Integrated with a high-efficiency dust collection system exceeding 98% capture efficiency, its two-stage filtration system captures even fine rust particles, significantly improving workplace conditions. The vehicle consumes only one-fifth the energy of comparable units, substantially reducing diesel engine waste heat and emissions. Its optimized exhaust and ventilation design fully meets operational requirements even without activating tunnel ventilation fans.

Picture 7 C-shaped Chips Generated During Rail Milling TrainOperations

Crystal-Clear and Serene New Energy Power

The FGM series rail milling trains offer users upgrade options featuring dual-power, hybrid, and fully battery-powered new energy solutions, delivering a comprehensive range of new energy power solutions for rail maintenance equipment. The key to achieving this new energy transformation lies in lightweight vehicle integration, high-efficiency traction transmission systems, and optimized operational systems. The FGM series of high-efficiency, intelligent rail milling trains achieve the optimal balance between cost-effectiveness and maximum range. Eliminating diesel engine emissions and noise, they deliver an exceptionally clean and quiet working environment, making them particularly suitable for tunnel operations in subway systems.

Picture 8 FGM500B Dual-Power Rail Milling Train (Guangzhou Metro)

Multi-Functional Solutions

The FGM series rail milling trains achieve a minimum cutting depth of 0.15mm. It is suitable for pre-grinding prior to new line commissioning, performing profile matching adjustments, eliminating welded joint irregularities, correcting rail base slope errors, and removing rail surface defects without generating scattered dust. Thesetrainsare also employed for corrective maintenance, leveraging its high efficiency and precision to thoroughly eliminate defects and restore tracks to optimal condition. When deployed for preventive maintenance, the trains achieve a processing capacity of 1.2 km/h. It requires no removal of trackside equipment or avoidance of civil defense doors, enabling continuous rail work within sections with optimal smoothness.

Full-Range, Full-scenario Rail Maintenance Capability

The FGM series rail milling trainsare the first domestically developed rail milling trains to achieve full-range turnout processing capability and successful market application. Their intelligent rail detection and positioning system accurately identifies obstacles, locates turnout sections, and intelligently calls up processing programs to achieve fully automated turnout processing. The FGM series rail milling trains can perform pre-opening grinding, preventive/corrective rail maintenance for subways, and efficient repairs for heavy-haul railways and industrial/mining railways. They operate in extreme conditions including tight curves, steep gradients, and narrow clearances, with a minimum working curve radius of 20 meters and a maximum working gradient (downhill) of 80‰.

Cost-Effective Full Lifecycle Service Capabilities

The FGM series rail milling trains exemplify lightweight, high-efficiency design. With an overall height under 3 meters, they can be transported via standard freight trucks, reducing relocation costs by 80%. Born for rail maintenance, the FGM series achieves full vehicle and core technology self-reliance for the first time, making equipment once priced over 100 million yuan no longer out of reach. The full-lifecycle big data platform supports 7*24 hours’ data analysis and health management, promptly addressing user needs and delivering scientifically optimized condition-based maintenance plans. The fully autonomous consumables supply and spare parts storage system ensures maximum lifecycle cost savings for users.

The FGM series rail milling trains feature clean, efficient, lightweight, and intelligent operation. As the only maturely commercialized next-generation rail maintenance equipment widely favored by users, they boast fully independent intellectual property rights and leading-edge technology. The FGM series rail milling trains are the preferred choice for rail maintenance service providers and an essential product for rail transit operators.

TsingInst Railway is committed to developing world-class intelligent rail transit maintenance equipment and providing comprehensive lifecycle rail maintenance services. The company offers a full range of rail milling trains, delivering timely maintenance services, cost-effective spare parts supply, rapid profile customization, and comprehensive operation and maintenance solutions. We welcome owners, experts, industry peers, and potential partners to engage in discussions and collaboration.