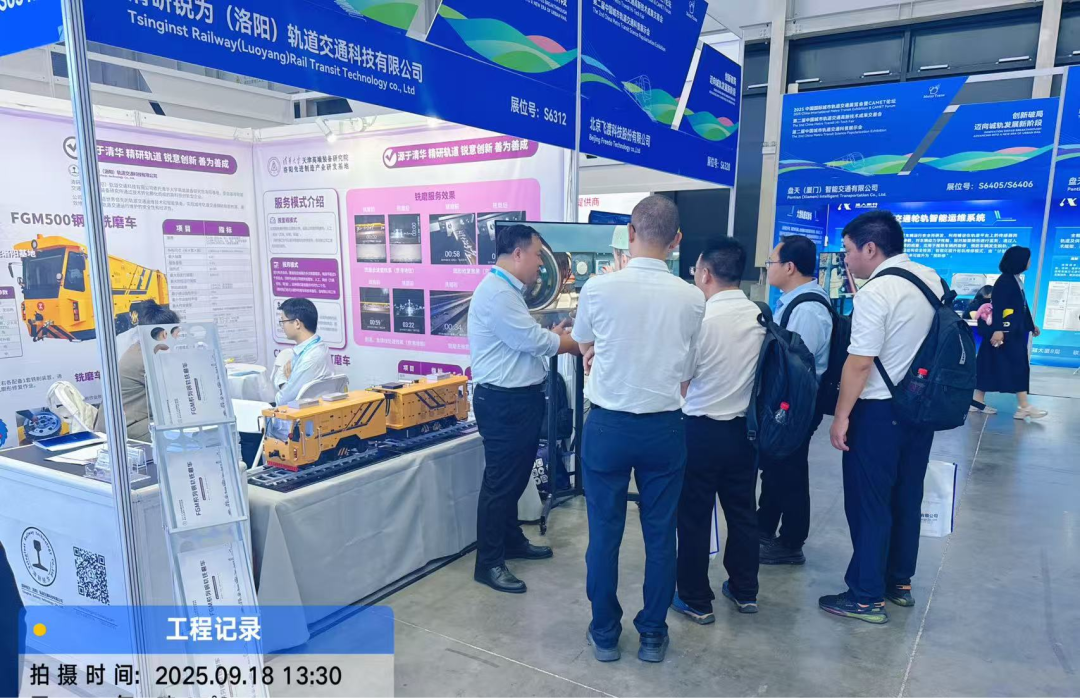

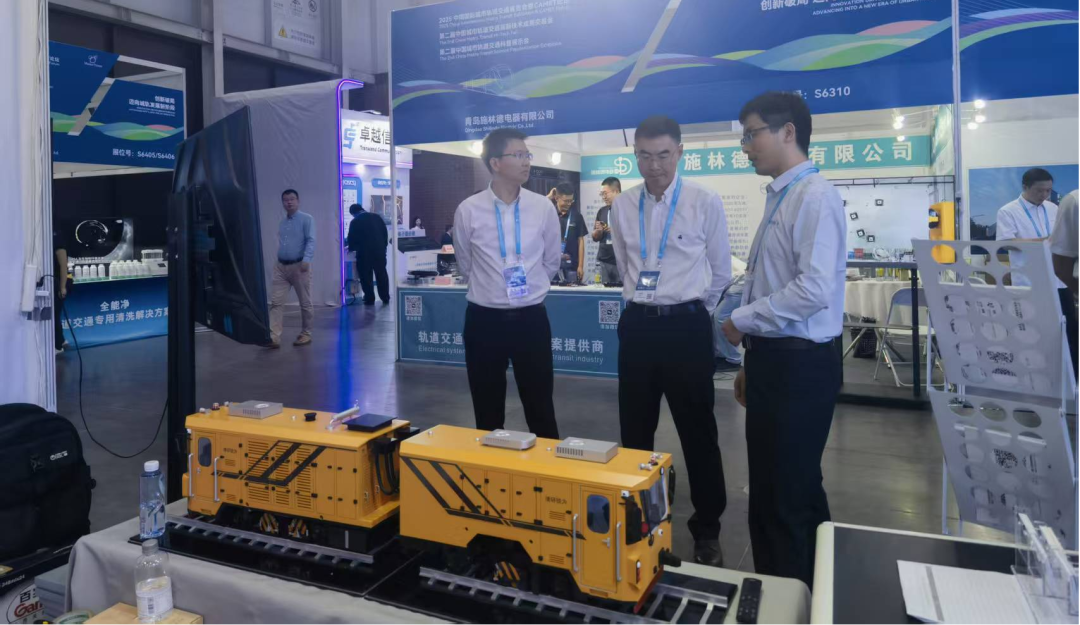

As a high-tech enterprise incubated by the Tsinghua University Institute of Advanced Equipment (Luoyang Base), TRT unveiled two independently developed products—the FGM500 rail milling train and the CMC-12 rail grinding vehicle — precisely addressing the core pain points of urban rail maintenance.Among them, the FGM500 rail milling train is hailed as a “rail defect doctor.” With its lightweight and intelligent design, it efficiently repairs common rail defects such as rail corrugation, head checking, and rail side wear. Furthermore, with a 99% collection rate of iron filings and a fire-free, clean operation mode, it resolves the long-standing safety and environmental challenges of traditional maintenance methods.The train also breaks through operational limitations by performing rail milling on turnouts and automated operations in special areas. Equipped with rail measurement functions compliant with the EN13231 standard, it realizes an integrated “detection–repair–assurance” maintenance model, comprehensively covers the requirements of efficiency, safety, and cost-effectiveness and provides a comprehensive solution to the efficiency, safety, and cost-effectiveness challenges in urban rail maintenance.

SUMMER

Notably, TRT not only showcased hardware products at this exhibition but also introduced rail milling services, forming a complete “equipment + service” solution. This provides urban rail operators with a new path to reduce costs and increase efficiency.Such a capability to transform technologies “from the research lab to the maintenance site” demonstrates TRT’s innovation-driven strength and further promotes the advancement of urban rail maintenance technology toward being “smarter, more efficient, and more reliable.” It highlights the responsibility and commitment of Chinese high-end equipment enterprises in the rail transit sector.